|

|

|

|

|

|

|

|

Boatyard in Nairobi

Specialized Mouldings (K) Ltd began in 1970 with one man, Milan Vesely, in an open sided shed.

Ten years later it had become a 5-acre, rail-served factory equipped with three 20-ton overhead cranes and comprehensive carpentry, steel and upholstery workshops—staffed by a very large team of all-Kenyan employees. Production consisted mainly of powerboats and industrial items until in 1977 when the Samantha 39 yacht was introduced.

Samantha-39 prototype

A 20-tonnes traversing crane has lifted the hull out of the mould and is now lowering it into the wooden frame, which was used to hold the yacht until finished.

Birth of the first Samantha hull "de mi Manera". The man in the yellow shirt lower left is Milan Vesely, owner of the boatyard.

Birth of the first Samantha hull "de mi Manera". The man in the yellow shirt lower left is Milan Vesely, owner of the boatyard.

Start of a production run

"de mi Manera" and "Alligande" side by side at the start of a production run.

"de mi Manera" and "Alligande" side by side at the start of a production run.

Several Samantha hulls

The photo shows several Samantha’s under construction in 1978.

The yellow hull upper right is “Alligande”.

The Samantha mould is to the left of three Samantha hulls.

The Samantha mould is to the left of three Samantha hulls.

The Factory

Nairobi, where the Specialised Mouldings (K) Ltd factory was situated is indeed 300 miles from the sea. It is at 5,000 ft altitude, weather mild (suitable for fibreglassing) due to altitude although on the Equator with 2 rain seasons. It was ideal for building the Samantha due to it being the most industrialized part of Kenya. Right behind the factory we had the main timber business in Kenya--hence the availability of good and exotic woods since Timsales (the company name) had a drying chamber.

You can still see the factory via Google earth by going to the following location: Jirore Road, Nairobi, Kenya. If you look at the corner between Jirore Road and Enterprise Road, on the south side of Jirore Road, you will see the 3 brown corrugated factory buildings, the corner office block etc. We owned and occupied the WHOLE corner back, some 5 acres, and you can even see the railway line coming into the rear of the factory. The employment at full was 500 staff with metal workers, carpenters, fibreglass people etc. There were 10 managers, 9 white, one African (my first employee)--all Kenya citizens. Ruth ran the office with 10 accountants, clerks etc while I did my thing overall.

We built the SM there. The three, 25 tonne overhead, moving cranes also helped. We could lift hulls, interiors etc easily. Everything was done there, including the fitting of the engines. Locally sold yachts even had masts, sails etc fitted in the factory. I had set up my own purchasing company in Cowbridge, South Wales, UK run by Ruth's brother Peter and they bought the equipment such as Proctor masts, Vetus winches etc and shipped them out to us.

Milan Vesely, April 2010.

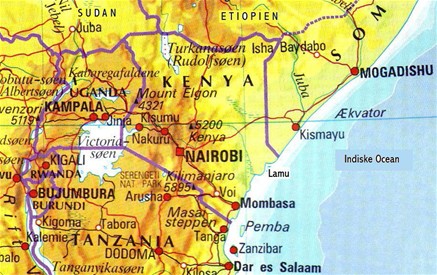

East Africa map

East Africa map

Boat transport

Once complete the yacht was placed in a steel cradle much like the wooden one shown in the first photo on this page. Then the yacht was transported on our own low loader down to Mombasa port.

The UK sold yachts were lifted in the cradle onto the ships deck, covered with canvas and strapped down before shipping to Southampton port in the UK. They were sent to Southampton without masts and sails, which were fitted at the marina in the Solent by Proctor's themselves.

Trusty low-loader. Here loaded with canoes, which was a part of the production.

Trusty low-loader. Here loaded with canoes, which was a part of the production.

Commander-34

The Commander-34 was a part of the production.

Mounted with machine guns two of them (one Ugandan and one Tanzanian) fought a sea battle on

Lake Victoria

when Tanzanian troops invaded

Uganda,

apparently with the intention of deposing President Idi Amin.

This is a 34-foot Commander on Lake Victoria -- sold to the Kenya Police.

This is a 34-foot Commander on Lake Victoria -- sold to the Kenya Police.

Searover-40

The Searover 40 ft was the most successful boat as far as sales went. “Designed by me, it easily carried two Land Rovers or one Mercedes or

Bedford

truck”, remembers Vesely.

Many were sold to

Uganda,

Southern Sudan

for the

Nile,

and

Zanzibar

.

The one shown belonged to my own company, Marine Services in Mombasa.

The one shown belonged to my own company, Marine Services in Mombasa.

|

|

|

|